Their vision, our solution

TALLMADGE SPINNING AND METAL

About Tallmadge Spinning and Metal

Tallmadge Spinning and Metal (TSM) is located in Tallmadge, Ohio. They have been in business

for seven decades (since 1947) and work with many leading companies in a wide variety of

industries. They have been owned by the Sasanecki family for 3 generations. They would say

the sky’s the limit when it comes to the industries Tallmadge Spinning & Metal serves, but

considering their experience in aerospace work, their ability doesn’t even stop there. They offer

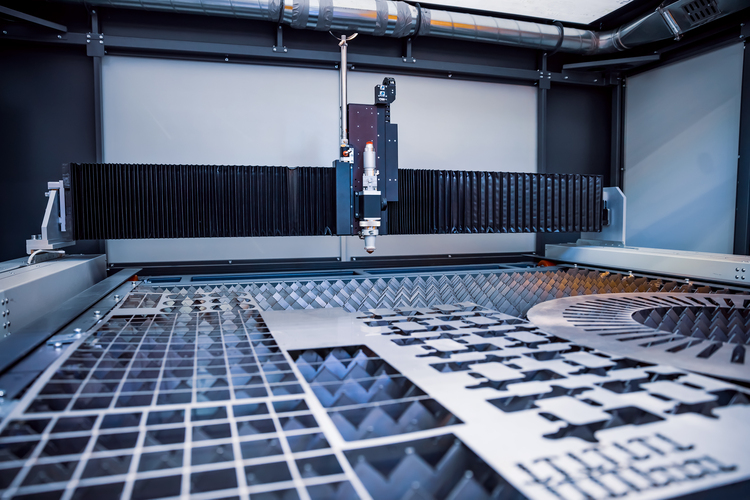

metal part production including laser cutting, welding, metal fabrication, metal stamping, metal

spinning and engineering.

Challenge

When we started working with TSM they were looking to replace their old Access database that

was no longer meeting their needs. They were looking for a brand new system that handled

their entire workflow from customers to invoicing and everything in between.

About Our Visionary

Mike Sasanecki is the visionary for the system at TSM. He is the VP of Sales at the company.

His team consists of his father, John and brother, Jake as well as his purchasing manager,

Steve and shipping manager, Don. They also have a full shop of employees who engineer the

products and an office staff that work with the system daily.

Vision

The goal for the new system was to allow management of customers, vendors, shop orders,

purchase orders, employees and time entries, invoices, parts, procedures, shipments and

reporting. We designed the system to have a main page and allow navigation from the main

page to any of the modules and from any of the modules to the related modules.

Ready to jump onboard for your own F*%@#$ amazing software?

Solution

The TSM system allows Mike and his team to manage their business all in one file. Everything starts with the customers. Customers have their own parts, inventory and orders. The orders are scheduled and shipped from the system and then invoiced to the customer. Purchase orders are sent to their vendors to bring parts into the shop for production. They are able to track time for production to get real costs for each order and run reports to give them a look at the financials for each order. We worked closely with them to achieve their vision and have been happily using the system for the past several years and we continue to work with them to add more value to the system all the time. Since launching the system it has been a very smooth process with very

few issues and we continue to enjoy our relationship with Mike and his team.